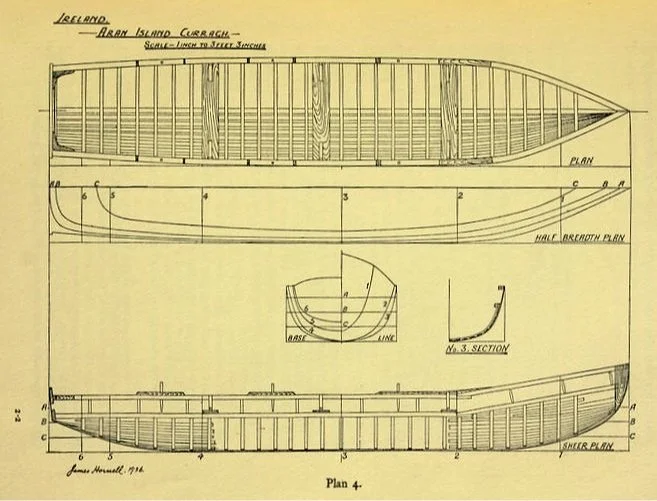

the building of our first currach

By members and friends of Hazelwood Boats built during the spring and summer of 2024.

First steps: The Gunwales

Lumber is sourced and milled to produce the correct size and thickness of materials required for the boat. This is often done by hand. Once the upper and lower gunwales of Douglas Fir have been attached to each other by the stanchions of Western Red Cedar, and the planks and knees of Oregon White Oak are in place for the seats, the process of installing the ribbing begins. Notice that the bow of the boat is also made of stronger Oregon White Oak.

next steps: the ribbing

Ribs of Oregon White Oak are soaked for an extended period, which renders them more pliable. They are then steamed and bent into shape by the builders who situate them parallel to the seats into slots on the lower gunwale. Once the ribbing is installed, the currach takes on its iconic profile. Notice that no nails have been used to secure the ribbing. Tension keeps them in place.

finals steps: strakes and skinning

To further reinforce the hull, strakes made of Western Red Cedar run perpendicular to the ribbing and are securely stapled into place. Once this process is finished, it's time to "skin" the boat. Traditionally, tarred hide or canvas is used to cover the hull. We, however, decided on ballistic nylon in order to withstand strikes from large woody debris that often flow down the Willamette and Columbia rivers. It has been tinted black to mimic the color of tarred canvas and stapled in place.